Every part specified, inspected, and dispatch-approved by a practitioner with 35+ years inside spinning mills.

Vaamana executes supply through carefully selected manufacturing partners. Responsibility for specification, inspection, and dispatch approval rests with Vaamana. The objective is simple: stable running, repeatable output, and predictable life — without trial-and-error.

Supporting mills in India and select overseas markets — with inspection-led dispatch approvals.

Why Vaamana →

Looking for a specific part or machine? Search directly.

Vaamana works with mills that value predictable running and disciplined execution. If the requirement is only “cheapest part”, Vaamana is not the right supplier.

Quality drift, waste control issues, frequent setting corrections, repeated stoppages.

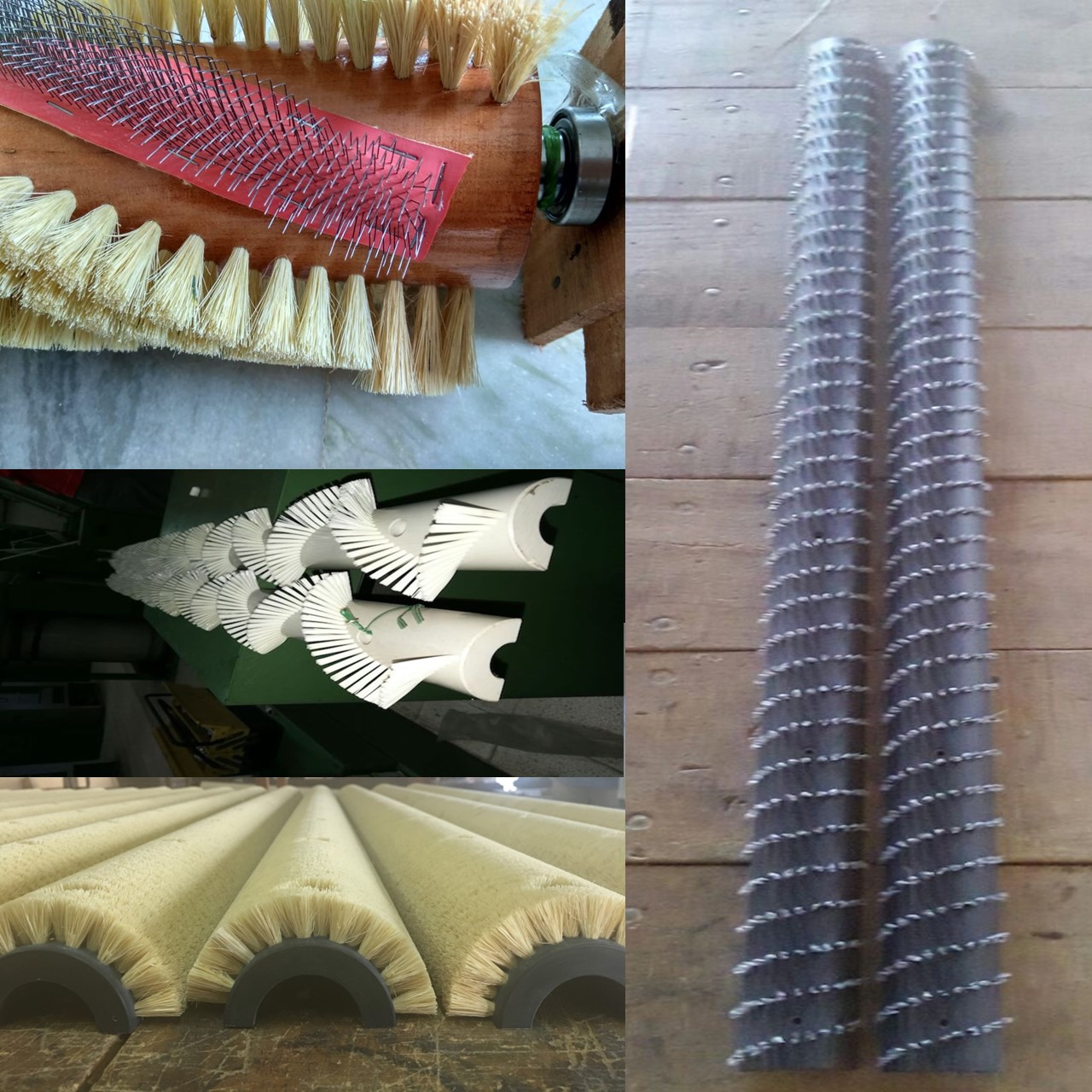

Pins, brushes, knives, and geometry affecting carding behaviour and life.

Repeat orders should run the same — not “depends on the batch.”

Carding-critical interfaces and consumables, executed with OEM discipline — not generic trading.

High-precision pin rollers and professional re-pinning services

Executed to preserve machine balance and long-term stability.

Select →

Professional-grade brushes and conversion services for carding and combing machines

Executed to preserve machine balance and long-term stability.

Select →

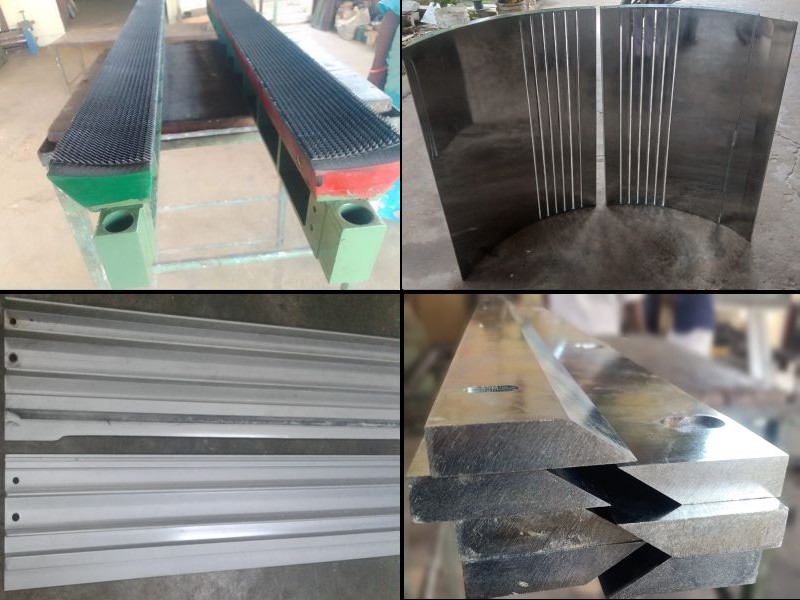

Engineering-led conversions and upgrades that restore interface discipline, improve waste control, and stabilise carding performance — executed with OEM awareness and application clarity.

Executed to preserve machine balance and long-term stability.

Select →

These spares are behaviour-critical interfaces. We supply OEM-aligned parts with controlled execution and fit — and confirm suitability by machine make/model and interface location through a Technical RFQ.

Executed to preserve machine balance and long-term stability.

Select →

Carding performance is depending on the setting accuracy of the machine. The Setting gauges are very important tool to set the card.

Executed to preserve machine balance and long-term stability.

Select →“Many mills contact us when visible wear appears — pins, brushes, or waste control instability.”

“Our role begins there: restore stable running without trial-and-error.”

Calm execution. Specification first. Inspection non-negotiable.

Recommendations grounded in mill behaviour — not catalog claims.

Selection depends on machine condition, application, and limits — not price alone.

Supply executed via partners, but inspection and approval rest with Vaamana.

Share the machine model, current issue, and what you're trying to stabilise. We start with a technical discussion — not a generic quotation.

For when you need carding expertise next time.

Or bookmark this page for technical carding supply.